Helphos Spotlights

As many of you will know, our current love affair is a 1967 Mercedes W111, better known as the Heckflosse or Fintail in English. As a rarely seen model it undoubtedly garners a lot of attention.

In period the Teutonic design was quite reserved, but these days the Mercedes star sitting atop the huge chrome grill, the flowing chrome adorned tail fins, and the vertical ribbon speedometer all attract a lot of interest.

It doesn’t take long though before the inquiring eyes fall upon the car’s greenhouse, and in short order the question always comes, “what’s that on the windshield?”

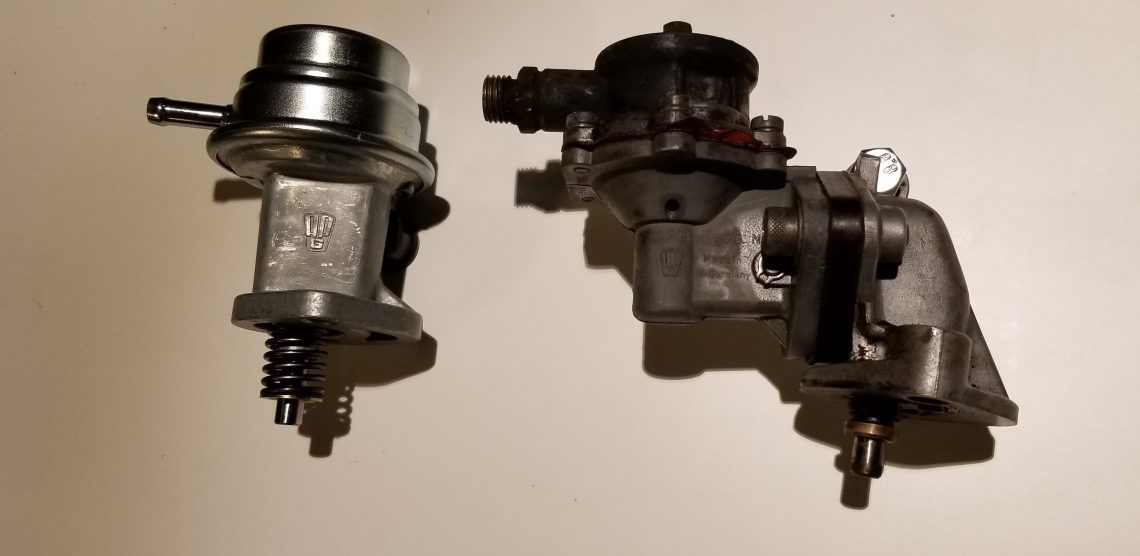

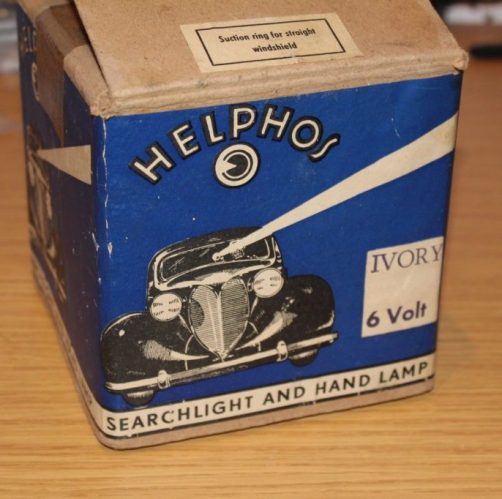

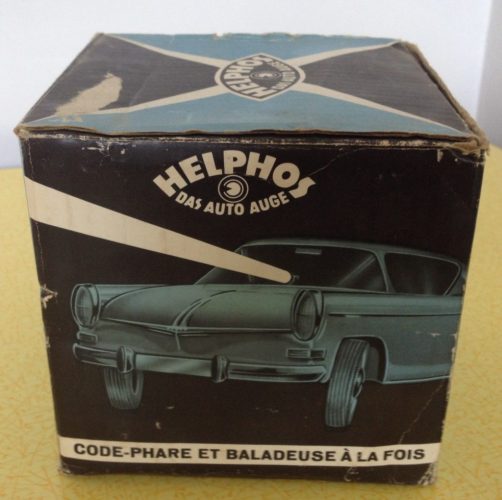

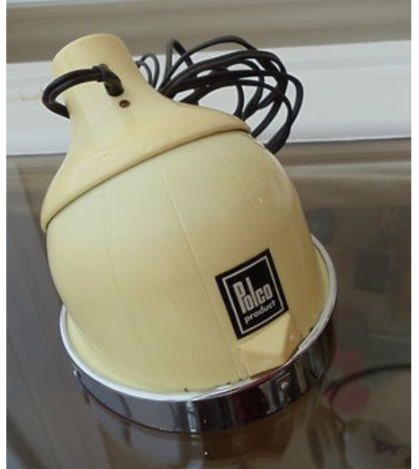

The Helphos “Eye of the Car” or “The Car Eye” is a German designed spotlight sold through the 50s and 60s that mounts directly to the windshield. The above photos show the evolution of the packaging during that time. The Helphos design was also rebranded under the names Polimatic, Polco (seen below), Les Leston, Marchal, and probably others.

Many cars as early as the 1920s sported spotlights, as road illumination was far less common and most signage didn’t use reflective materials. These spotlights were often attached to the A pillar or the front wing (fender) and required reaching outside the car to operate. While many were strictly spotlights, combination units with a spotlight facing forwards and a mirror facing rearwards were a common accessory for decades right into the 60s. Eventually however, spotlights mounted on and through the A pillar made it to the market. These were controlled from within the cabin via a handle and linkage and while quite common on police and fire vehicles were less common with the average car owner as few owners warmed up to the idea of drilling through the A pillar.

While the infamous British automotive electrics company Lucas had their own solution to reaching outside the cabin, it was not nearly so elegantly devised. Lucas sold a roof mounted light that looked and operated much like a submarine periscope. The light was unsightly and (with a large handle invading the cabin) intrusive. Perhaps the biggest drawback was that it required drilling a hole in the roof of the car. As such it really was only popular with the most dedicated British rally teams, and was never adopted by the general public as the Helphos was.

The Helphos spotlight was novel as not only could their design be used from within the cabin, the light itself was inside the cabin. Not only was the user protected from the elements while directing and focusing it but the light was protected from damage from flying road debris. All this was accomplished without alteration to the vehicle. Not only could the end user install the light themselves, with installation being non-invasive the light could be switched from car to car in an instant.

While popular for many recent years with the aircooled Volkswagen folks (who adore their period accessories) the Helphos spotlight is really otherwise unknown these days but for a niche group of period endurance or navigational rally enthusiasts. While the Helphos light was used by many rally teams, Mercedes was especially fond of them. In fact it is rare to find a period photograph of a Fintail rally car where the vehicle is without one.

As we always envisioned building the Fintail into a ‘period’ rally car, it was practically essential to install one to complete the look. We actually owned the light before taking possession of the car itself.

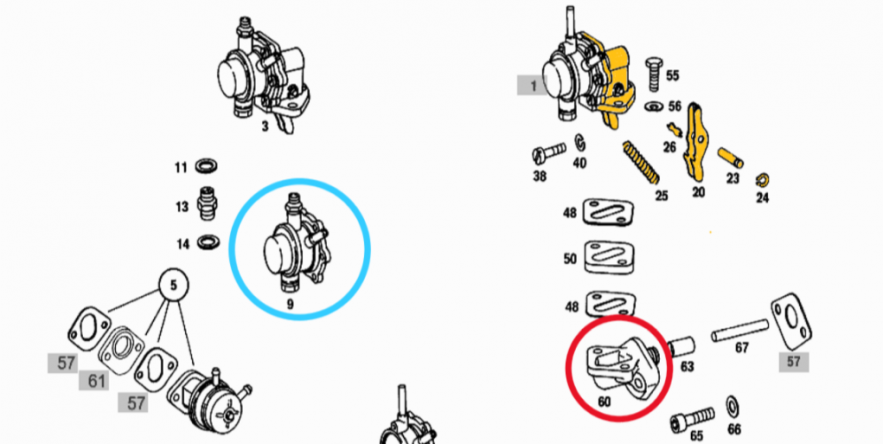

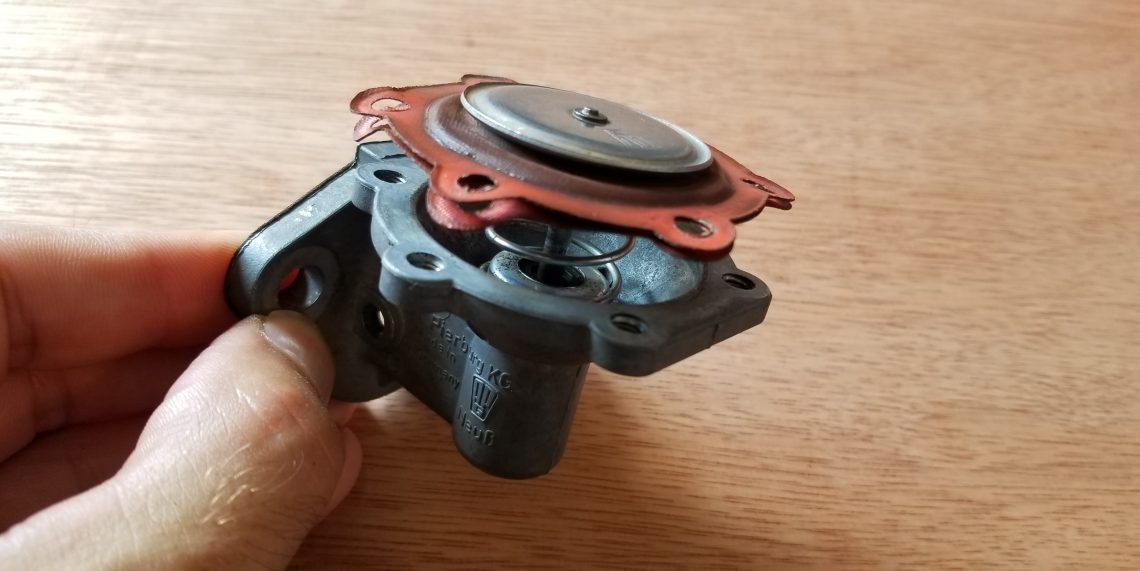

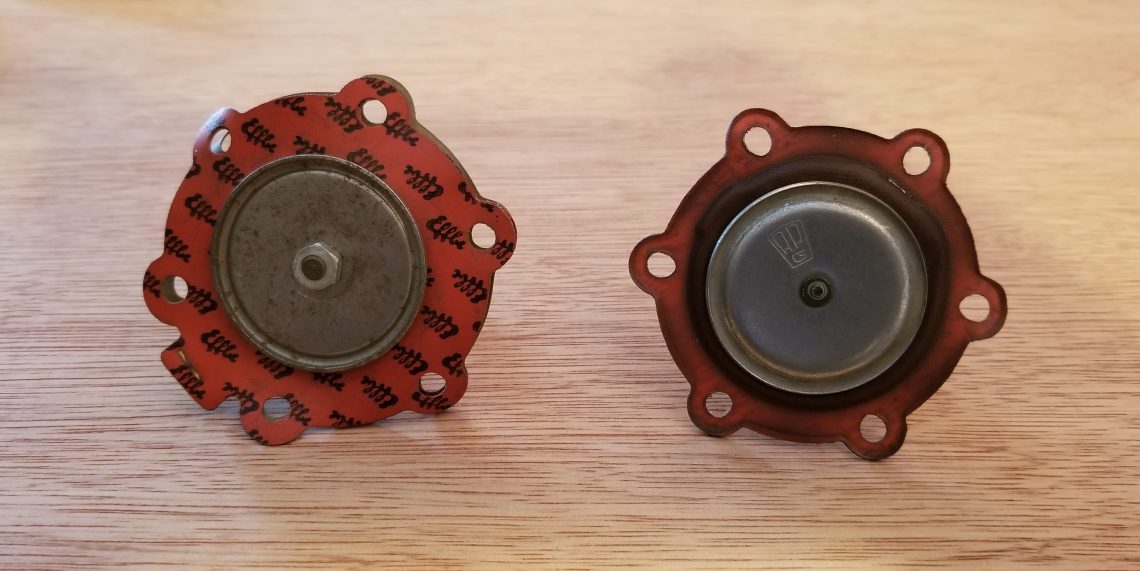

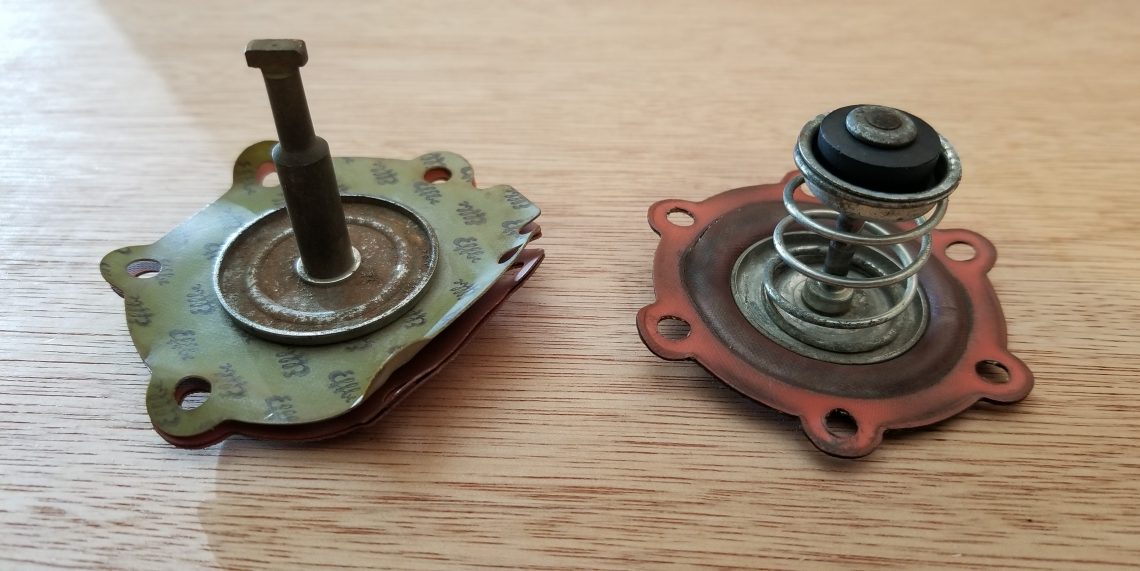

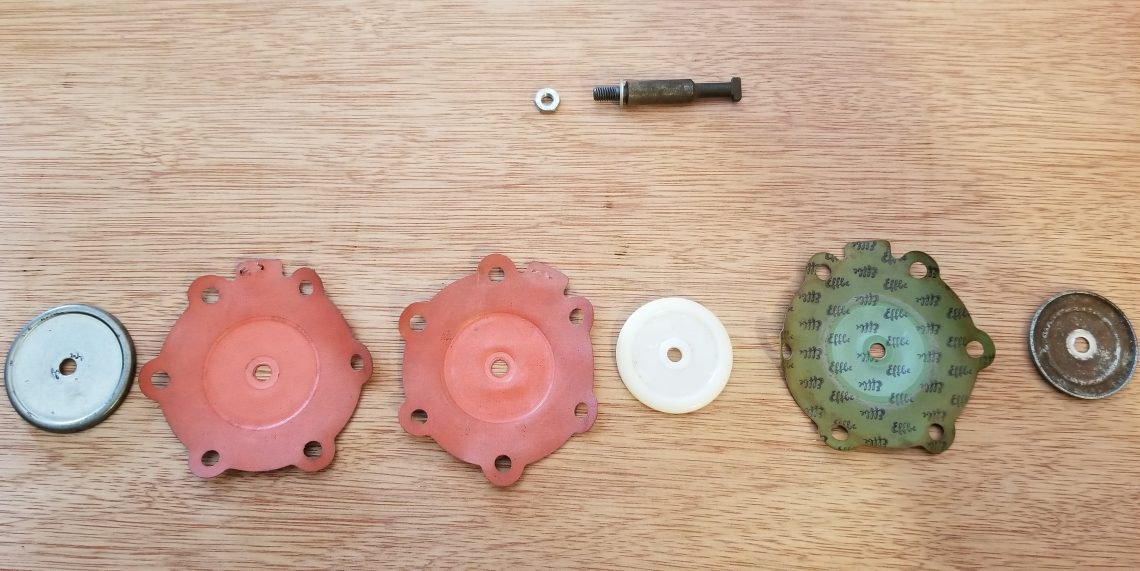

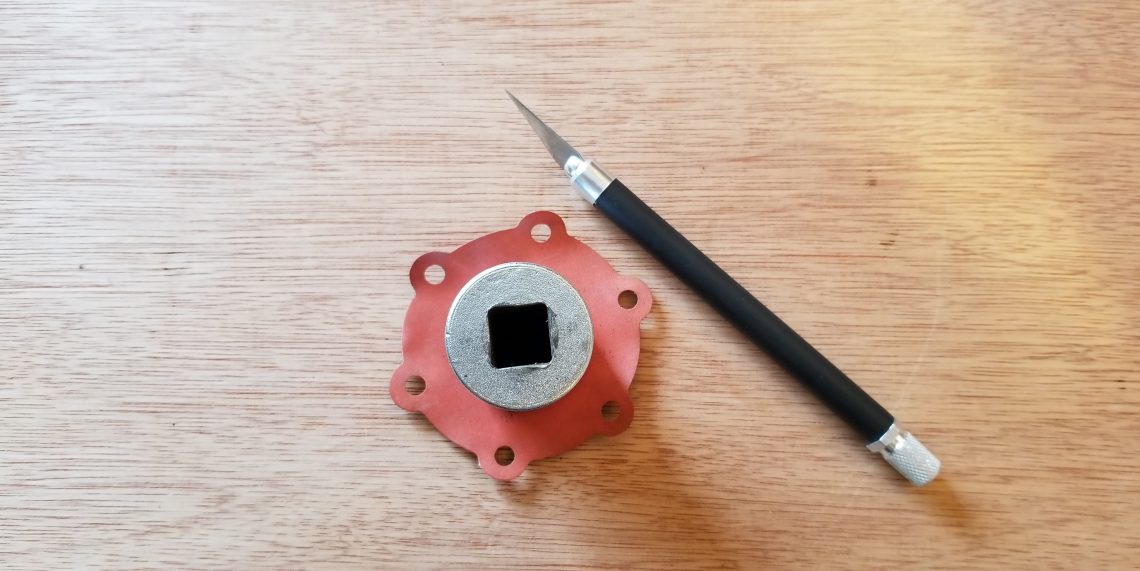

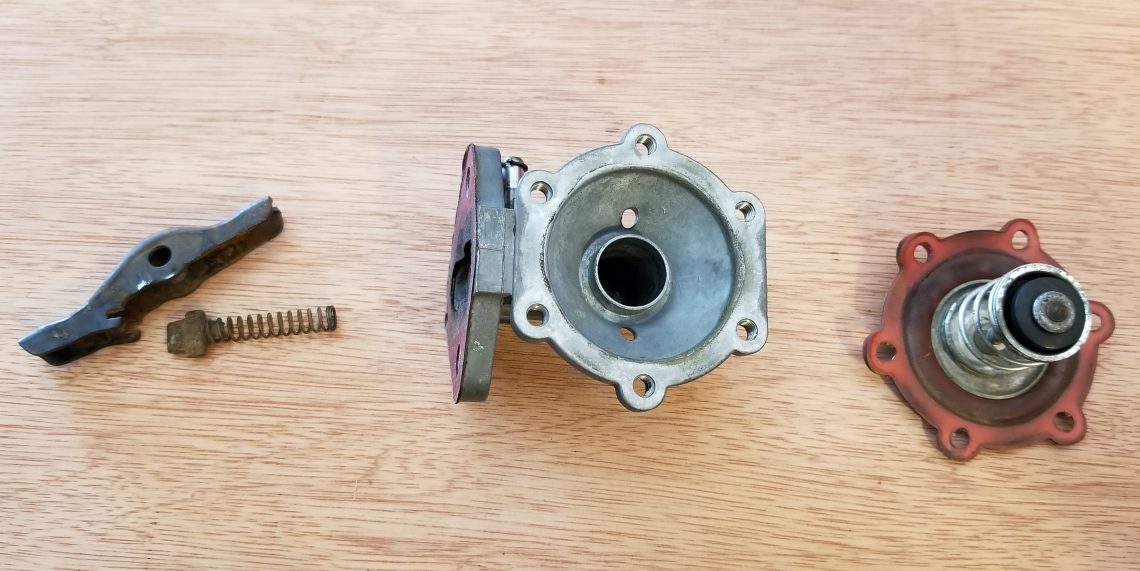

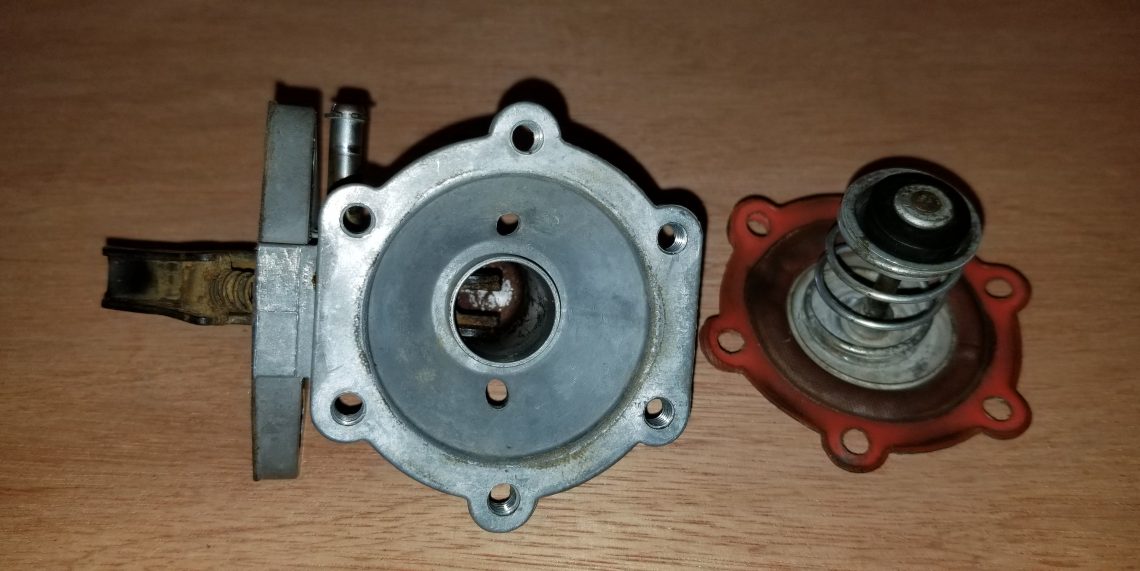

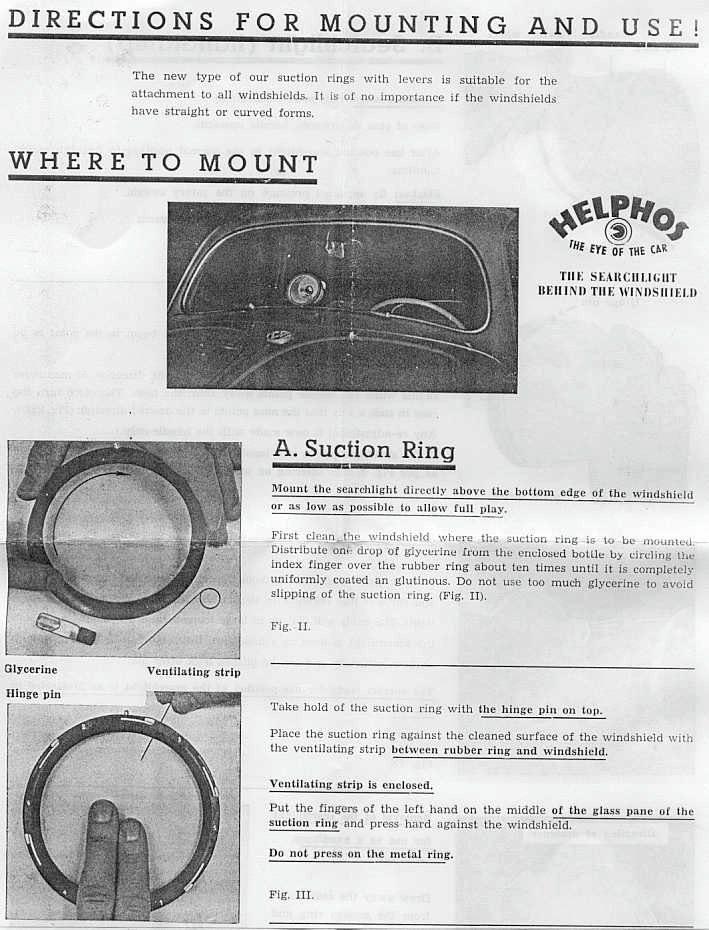

The light is actually comprised of two main parts, a metal mounting ring with embedded glass that attaches to the windshield and the light body itself that hangs from the mounting ring. The early version of the mounting ring seen above was a simple design as the flat windshield screens of the time posed little challenge to adhesion. However as curved glass became common the mounting design (seen below) necessarily became more complex.

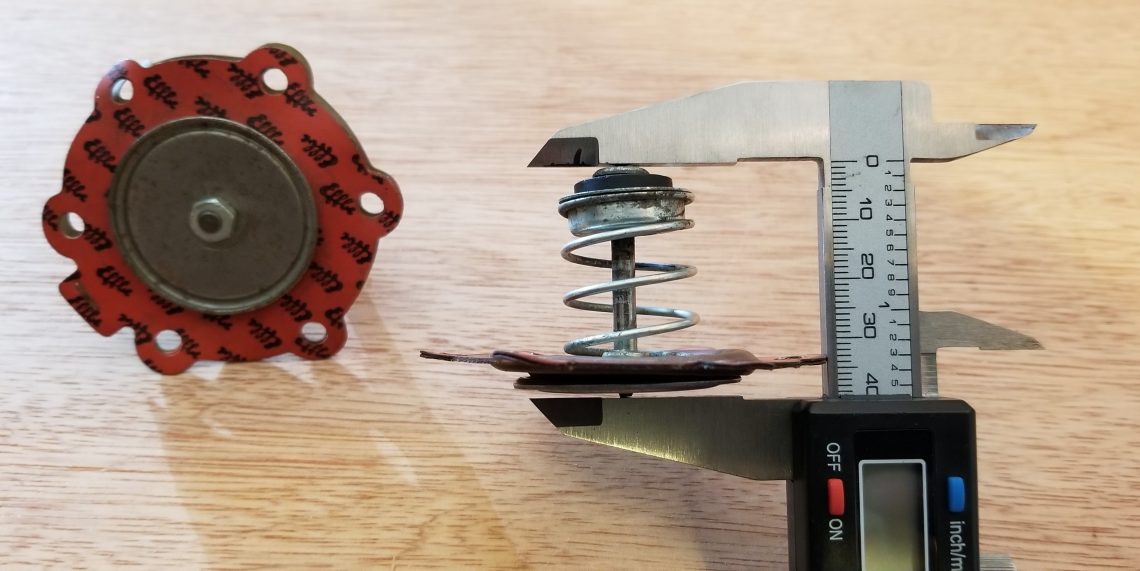

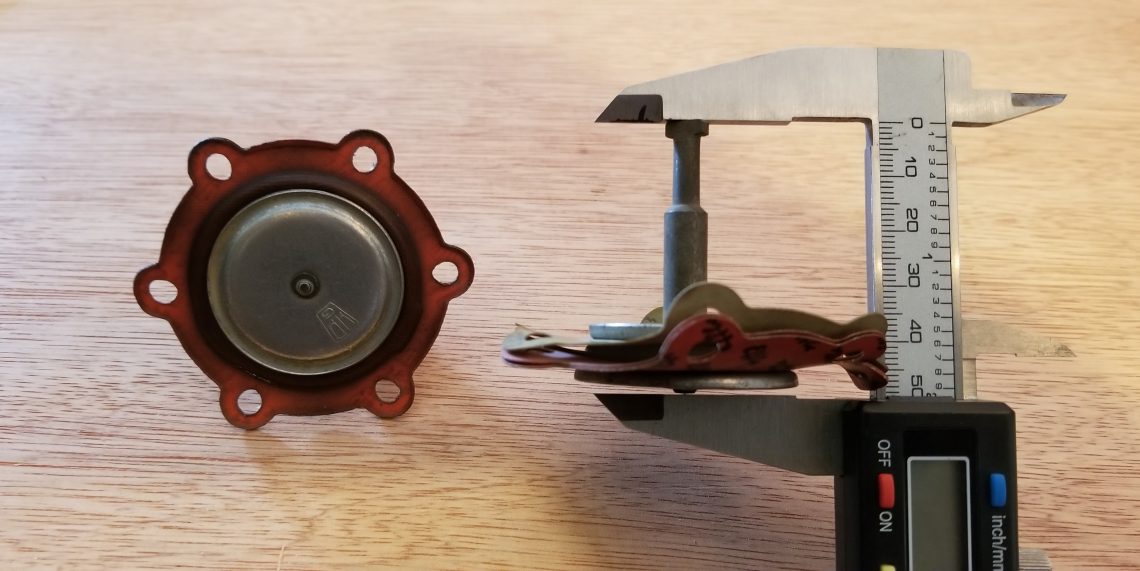

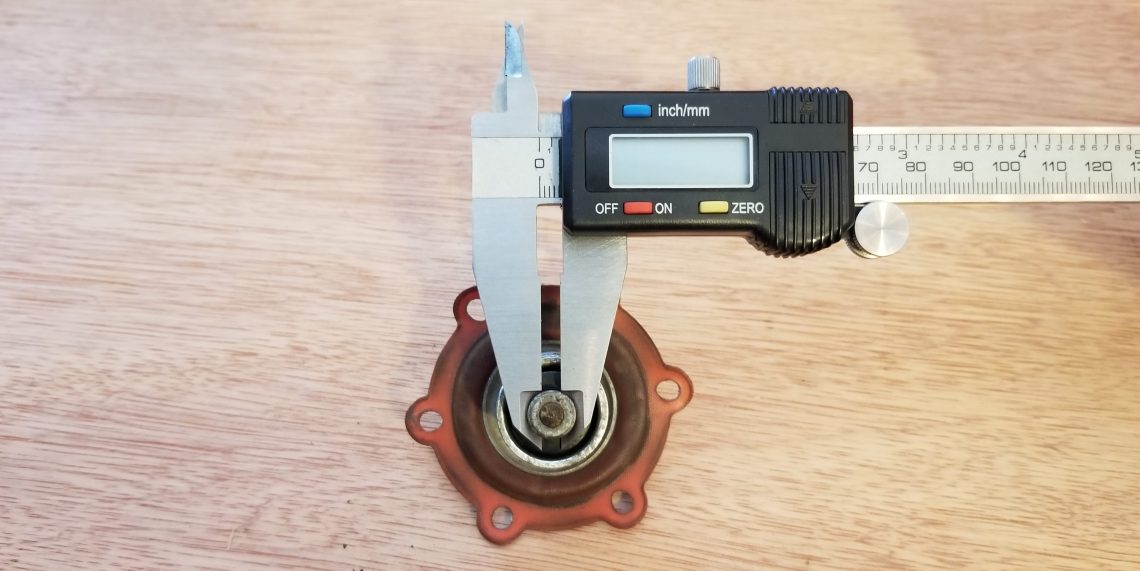

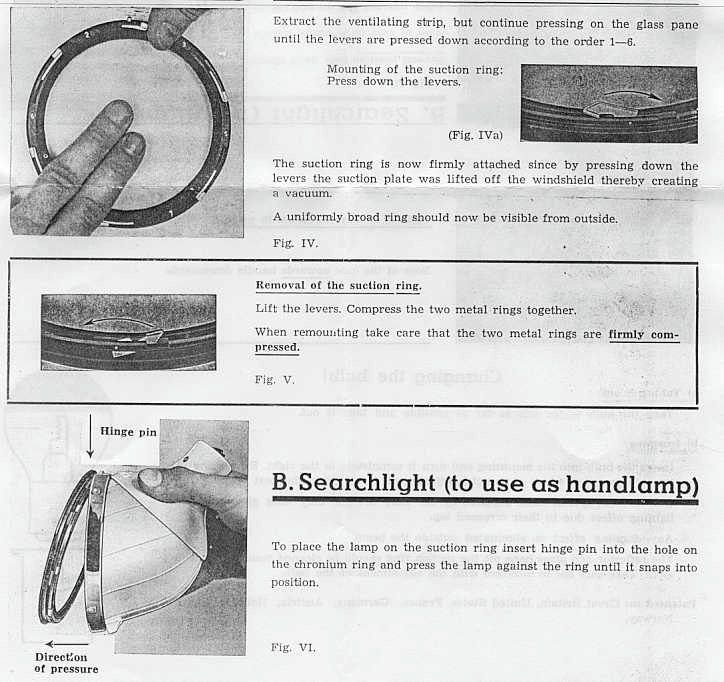

The later mounting ring is actually two separate hinged rings, with a rubber seal that is placed against the glass. Numbered levers along the circumference of the ring are swung in consecutive order while the rubber seal (smeared with a dab of included glycerin) is pressed against the windshield. A thin wire is included that is placed under the edge of the rubber gasket.

The wire allows the air trapped between the windshield and the mount to escape as the glass of the mounting ring is pressed towards the windshield. The ventilation wire is removed and the levers are thrown pulling the two halves of the ring apart. The result is an incredibly effective vacuum mount.

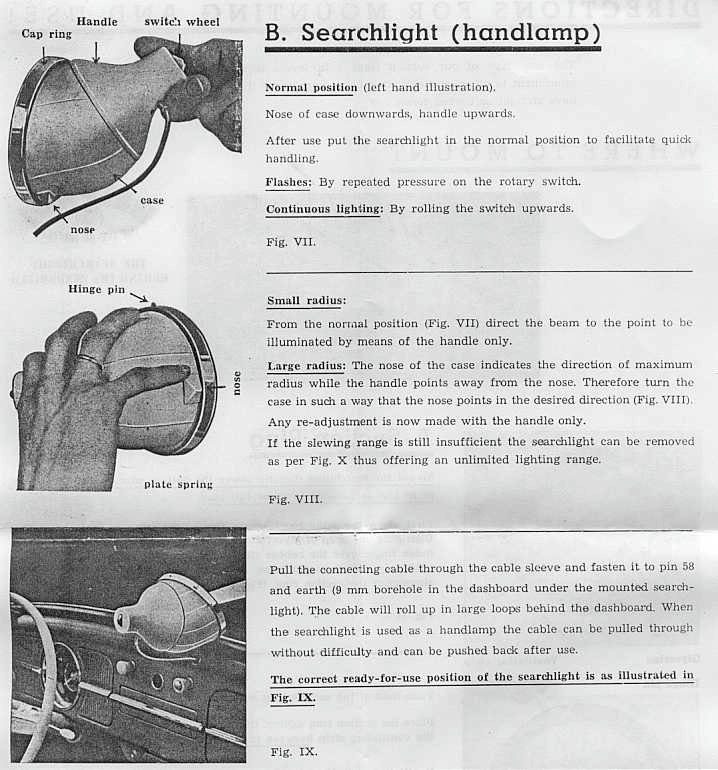

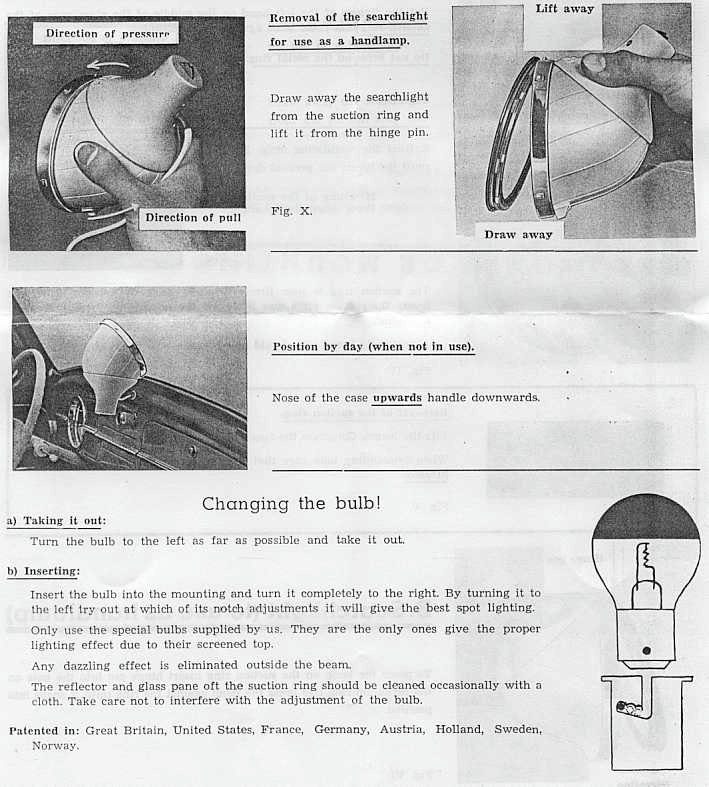

The main body of the lamp hangs from this ring and can be removed independent of the ring. With the freedom provided by the included generous length of electrical wire, the Helphos is effectively used as a handlamp for roadside repairs. Clearly this was another added bonus over most other available spotlights of the time.

While mounted on the windshield the light beam can be used to illuminate street signs, markers or roadside features. The Helphos had another design advantage over most other spotlights as the beam itself could be focussed from narrow to wide beam simply by rotating the main body in a clockwise fashion. Directing the chosen beam to the target was as simple as moving the handle.

While generally uncommon, the Helphos lights are still readily available in enthusiast circles, and eBay, even NOS (new old stock) lights are fairly common. For the best prices, avoid any Volkswagen enthusiast sites, and German specific parts houses which tend to soak the eager enthusiast. Using some creativity in search terms and locations (these lights are far more common in Europe) along with some patience can save you enormously. Ours came from England and even with the added cost of shipping we came a hundred or more dollars under the price of most North American sources.

While it’s best to confirm the electrical operation before purchase these are simple in construction, and easy to rewire if necessary. While many Helphos lights now have male cigarette plug adaptors, in period they were sold with bare wire to install as the customer saw fit.

Any potential buyer needs to ensure that the reflector and especially the rubber gasket are in good order. A dried, torn gasket will absolutely prevent the light from adhering to the windshield, while a peeling or tarnished reflector will greatly reduce the light output.

The bulbs, while still available, aren’t common and tend to range greatly in price. Confirm that a bulb is included and working and consider combining the cost of shipping with a spare if the seller has them available. The least expensive bulbs, lack the blackout painted end however this is easily replicated with some spray enamel.

The following are the Helphos installation instructions, explaining the mounting of the ring to the windshield, basic operations, and bulb replacement.

This article requires a couple acknowledgements. First to Elliot Alder for the lead photo of our Fintail, one of our absolute favourites.

Second a special thank you to Mercedes Benz that permits access to and use of the historic racing photography you see in the article.

© Daimler AG.

All data and content are protected by copyright. Use of the data and content requires the source to be stated.

The global copyright remains the property of Daimler AG.

As always, comments and questions are welcomed. We strive to provide accurate info however if you have spotted a mistake, or simply have more to add please let us know. All our articles are perpetually updated and revised as needed.

We’ll leave you with another historic Fintail rally photo – cars complete of course with Helphos lights.